- Privacy

- News

- Blog

- Brand Assets

© Copyright 2023. GSTX Ltd and Subsidiaries. All rights reserved,

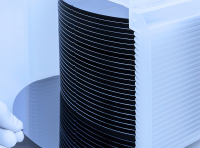

A silicon wafer is the thin piece of ultra-pure mono-crystalline silicon that forms the core of a solar cell. These wafers are a crucial element in the production of solar cells and semiconductors.

High-Purity Quartz

Quartz Crucible

CZ Furnace

Silicon Ingot

Silicon Wafers

© Copyright 2023. GSTX Ltd and Subsidiaries. All rights reserved,

We collect cookies to analyze our website traffic and performance; we never collect any personal data. You can learn more about our data usage by clicking Privacy Policy.